What we can do ?

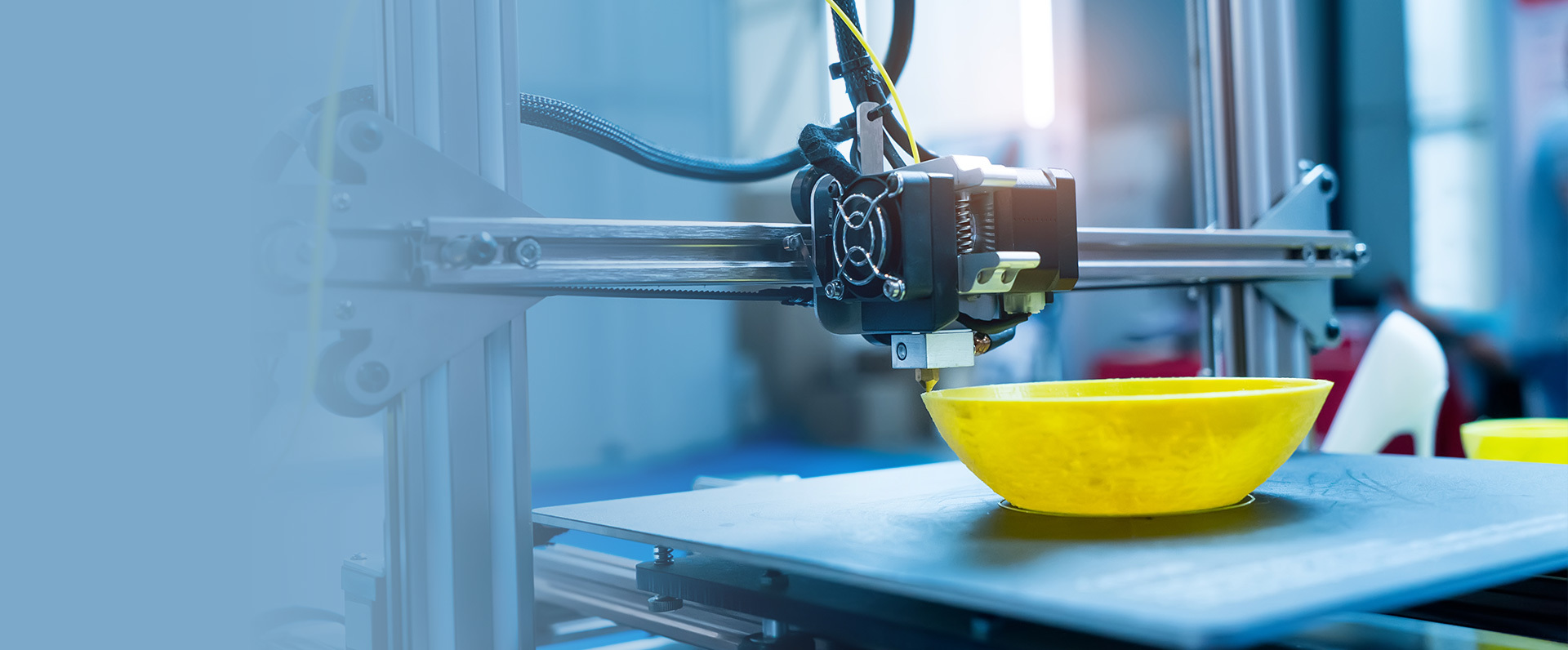

Imagination Meets Innovation in Every Toy We Create

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

Audio & Electronics Engineering

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

About Us

JETECH ELECTRONICS was established in 2011 as a full service contract manufacturer in the electronics and plastics industry. Our company focuses on core values below that are fundamental in achieving and maintaining our high level of reputation in the production of quality, cost-effective and innovative products for our customers.

Established in

Contract manufacturing service

Customized privatemolds

Our Strengths

Cooperation Partner

Imagination Meets Innovation in Every Toy We Create

JETECH ELECTRONICS was established in 2011 as a full servicecontract manufacturerin the electronics and plastics industry.

News & Media

News & Media